Clean room

Clean room

In the realm of controlled environments, Technical for engineering services (T.E.S) stands as a beacon of excellence, delivering comprehensive clean room solutions tailored to meet the unique demands of various industries. Ensuring that every aspect of the clean room aligns seamlessly with the stringent requirements of Good Manufacturing Practices (GMP).

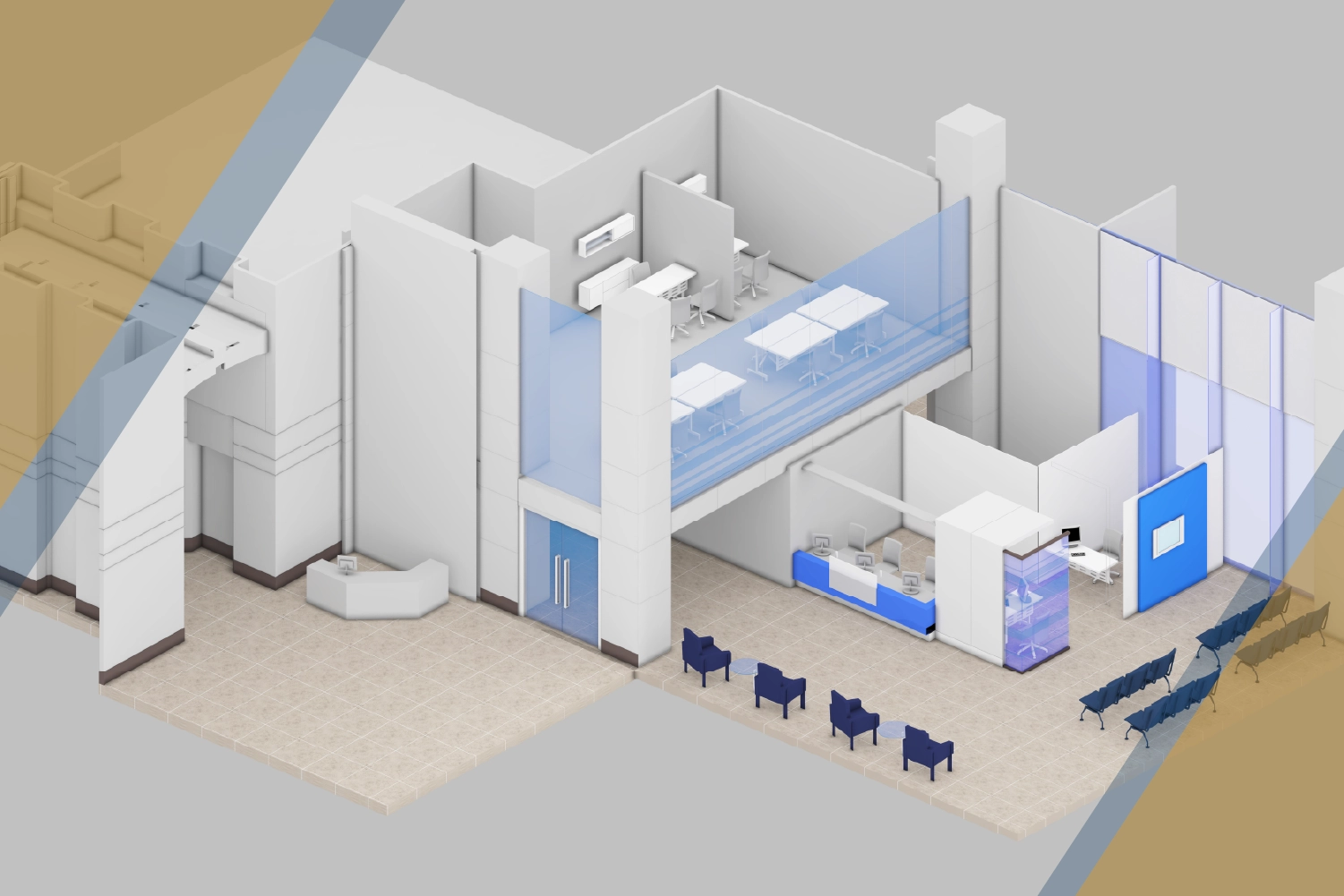

Clean room Design

T.E.S designs GMP-compliant clean rooms for pharmaceuticals, biotech, medical devices, and electronics. We optimize airflow, ensure scalability, and maintain strict contamination control. Our turnkey solutions combine precision engineering, regulatory compliance, and validated performance for every industry’s needs.

Codes and Standards

We prioritize compliance with the highest industry standards throughout the installation process. Our team is well-versed in Good Manufacturing Practices (GMP) and Ministry of Health regulations, we conduct rigorous quality checks at every stage to guarantee that the final product meets the specified standards.

Installation

By combining our technical expertise with a meticulous approach to installation and a steadfast commitment to regulatory compliance, we deliver clean room solutions that are not only functional and efficient but also fully compliant with industry standards and regulations. Considering the following:

Hygienic Doors

- The installation of hygienic doors is crucial for maintaining the integrity of the clean room environment. These doors are designed to minimize the introduction of contaminants and are seamlessly integrated into the overall structure

Epoxy Flooring

- The epoxy flooring is carefully installed, ensuring a smooth, seamless, and easy-to-clean surface. This specialized flooring is resistant to chemicals, abrasion, and impact.

Panels

- The installation of the panels is a critical step in creating the clean room environment. Our team ensures that the panels are precisely aligned and sealed, creating an airtight barrier against contaminants.

Pass Box

- The pass box is a crucial component of the clean room, enabling the transfer of materials between different contamination levels without compromising the integrity of the environment.

False Ceiling

- The false ceiling is an integral part of the clean room infrastructure, providing a smooth and easily cleanable surface while concealing the HVAC system and other utilities.

HVAC System

- The HVAC system is critical for maintaining the controlled environment within the clean room. Our team carefully installs and calibrates the HVAC system to ensure that it provides the required temperature, humidity, and air filtration levels.

Lighting Fixtures

- Provide appropriate illumination levels within the cleanroom while minimizing the introduction of particulate matter Considering using LED lighting fixtures with perfect illumination level.

By carefully considering these elements and adhering to strict quality control measures, we deliver clean room installations that meet the highest standards of performance and reliability.

Testing

Ensuring the integrity and functionality of a clean room after installation requires a comprehensive validation process. This involves a series of rigorous tests and procedures designed to verify that the environment meets specified cleanliness standards and operational requirements. The following points outline the key tests and procedures performed during clean room validation:

- Particle Counting

- Microbial Testing

- Differential Pressure Testing

- HEPA Filter Integrity Testing (DOP/PAO Test)

- Air Velocity and Airflow Pattern Assessments

Related Projects

Project Name

Nutritional Supplements Production Floor

Address

Industrial zone- Gamasa, Egypt

Project Timeline

From 8/2024 to 9/2025

Project Name

Cream production line extension

Address

Borg El Arab, Alexandria, Egypt

Project Timeline

From 9/2024 to 9/2025

Project Name

Clean rooms Nile pharma project

Address

Alameria - Cairo, Egypt

Project Timeline

From 3/2024 to 7/2024

Project Name

Hospital

Address

El Nahda- Alexanderia, Egypt

Project Timeline

From 8/2022 to 9/2023

Project Name

Pure Cosmetics factory

Address

Menoufia, Egypt

Project Timeline

From 7/2022 to 3/2025

Project Name

Beauty Care Cosmetics factory

Address

Beheira, Egypt

Project Timeline

From 1/2022 to 10/2023

Project Name

Wet Ever Cosmetics Factory

Address

10th of Ramadan city -Cairo, Egypt

Project Timeline

From 12/2020 To 12/2023

Project Name

LEVEN Cosmetics factory and Steel structures

Address

Borg el Arab, Alexandria, Egypt

Project Timeline

From 9/2016 to 3/2020 and from 8/2023 to 8/2024